New to Engineering? No Problem: Research Assistant Zoë Dietrich builds her own carbon-monitoring chambers

These low-cost, floating chambers autonomously measure emissions from ponds in the Arctic and the Amazon

Zoë Dietrich checks on the internal mechanism of one of her chambers.

photo by Mitch Korolev

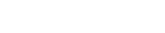

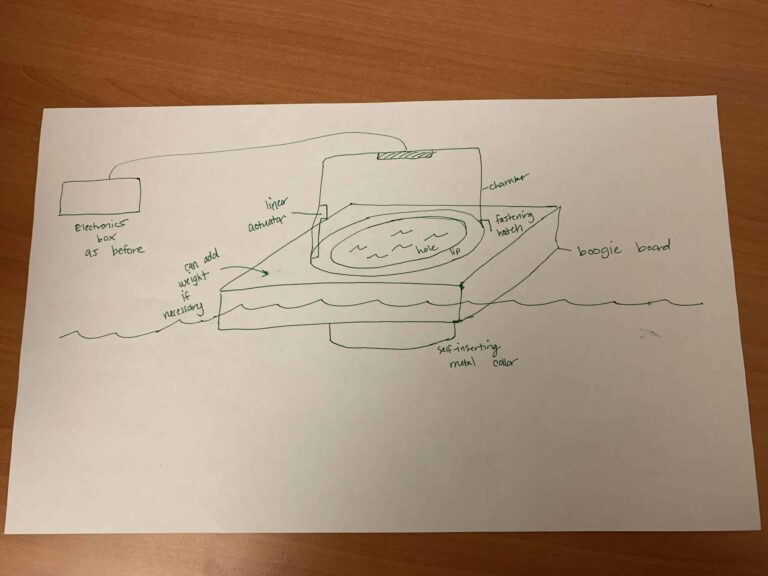

“Why not float the aquatic greenhouse gas chamber on a surfboard?” Tropics Program Director Dr. Mike Coe suggested in one of our team meetings, and I felt the gears in my brain begin turning. I started a sketch… If mounted on a surfboard, we would need a method to open the chamber, flushing it with outside air. Back in my office, I asked Google “what turns electrical energy into mechanical energy?” Google was quick to respond, “Motor.” Right, thank you, Google. Next, I typed, “motor that pushes something up.” Google replied, “linear actuator.” Three clicks later and I had ordered my first linear actuator for 35 bucks.

Three days later, that linear actuator sat expectantly on my desk. One red wire and one black wire, “12V DC” printed on its side. I turned back to Google, “How to wire a linear actuator?” Opening the first hit, I skimmed through the photos and diagrams. None of them striking my fancy, I moved on to the second hit: Step-by-step instructions, clear photos, even open-source code to program my Arduino microcontroller board–nice! Within an hour, my linear actuator was extending and retracting on command, ready to be mounted in an autonomous greenhouse gas chamber.

Adding the actuator to my sketch, I popped into Senior Research Scientist Kathleen Savage’s office to hear her thoughts. Savage always has new ideas brewing, and she suggested adding a feature that would allow the chamber to function on water and on land. The chambers are the product of a Fund for Climate Solutions (FCS) grant led by Savage to quantify carbon dioxide and methane emissions from small water bodies like lakes, ponds, and reservoirs. Because there are no low-cost and auto-sampling tools available on the market, we have been developing a new instrument to measure these emissions.

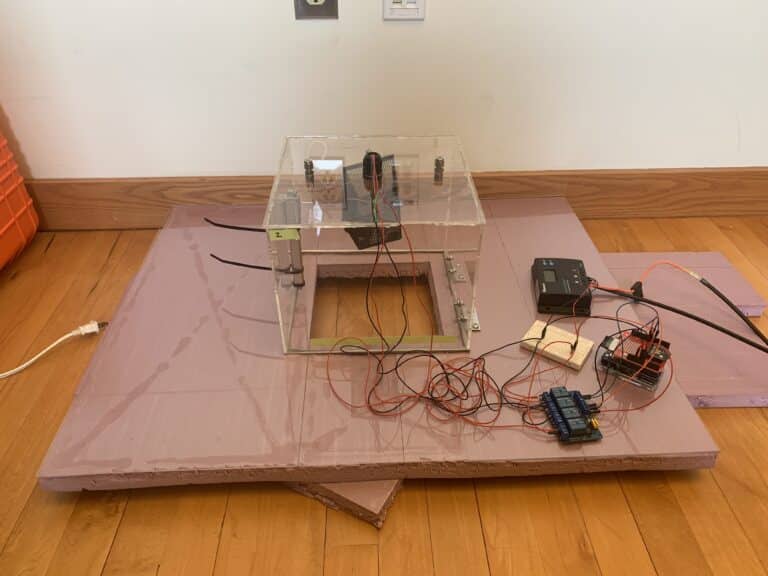

A sketch (left) and prototype (right) of the first floating methane chamber.

photos by Zoë Dietrich

DIY science

“Chamber” is a fancy word for the upside-down buckets we use to measure how fast greenhouse gasses are released from different surfaces. By resting a bucket upside-down on a patch of soil or grass or water and measuring how fast gas concentrations increase or decrease inside the bucket, we can calculate a “flux” of gas over a set area and time. Common methods of measuring fluxes require manually collecting gas samples from a chamber to be processed in a lab, or connecting the chamber to a high precision analyzer that can cost around $40,000. These methods are costly in salary time and equipment, limiting where, when, and how often people can sample—usually daytime and in accessible areas and times of the year. We need new low-cost and autonomous systems that can measure around the clock to improve carbon emissions estimates. The recent commercialization of cheaper sensors and control systems to operate them, like the Arduino microcontroller, now make these developments possible.

I’m building a new floating chamber that measures aquatic fluxes autonomously using a $15 methane sensor and a $78 carbon dioxide sensor, improving previous designs published by Dr. David Bastviken’s group at Linköping University in Sweden. Powered by a solar panel and battery, the sensors measure gas concentrations, temperature, and humidity inside the chamber every 30 seconds. The data is stored on an SD card and transmitted within 50 meters via radio. The radio transmission allows us to check that the chamber is functioning properly from the shore and to see chamber measurements in real time. When gas concentrations have increased enough to discern a flux, the linear actuator extends to open the chamber, flushing the interior with outside air before retracting to close the chamber again for another flux measurement. Calibrating the chamber with a high precision analyzer in the field shows the low-cost sensors perform well, with an accuracy of approximately 1 ppm for methane and 3 ppm for carbon dioxide.

Dietrich assembles the first of her methane chambers for deployment.

photo by Marcia Macedo

Field deployment

I first tested chamber prototypes last July on agricultural reservoirs at the Tanguro Field Station in Brazil. At the end of our field campaign, I left one chamber deployed to see how long the electronics would last and which components might eventually fail. After helping me deploy and calibrate the chamber, field technician Raimundo “Santarém” Quintino monitored it, checking its “vital signs” via radio every few weeks. In January, he noticed the linear actuator had stopped pushing the chamber open.

During a follow-up field campaign in March, I brought a couple of extra linear actuators and five more chambers to deploy on additional reservoirs at Tanguro. Tanguro staff and I worked together to modify chamber components that didn’t function well in the first deployment. These modifications included swapping the materials of the floating foam bases and improving the mounting mechanisms of the linear actuator and chamber hinge. Our adjustments were informed by recommendations from a Laboratory Operations Manager at the University of Maine in Orono (Christopher London), whom I met while doing fieldwork at the nearby Howland Research Forest. Woods Hole locals, such as John Driscoll and Fred Palmer of the Woodwell Climate Facilities department, kite foiler and carpenter Tad Ryan, and employees at Eastman’s Hardware, have also offered transformative recommendations on building materials and techniques to stabilize the floating chambers.

Dietrich and Tanguro scientific projects coordinator, Leonardo Maracahipes-Santos, assemble the methane chamber base.

photo by Mitch Korolev

Working hands-on with the floating chambers on the reservoirs, Santarém, Dr. Leonardo Maracahipes-Santos, Tanguro’s Scientific Projects Coordinator, and Sebastião “Seu Bate” Nascimento of Tanguro Field Station have made invaluable improvements to the chamber design and deployments. A few of their contributions include advice on safe deployment locations, monitoring and collecting data from the chambers over time, and constructing aluminum and galvanized steel components for the floating bases. They also designed a new mount for the most recent chamber addition—a bubble trap that uses an inexpensive pressure sensor to autonomously measure the volume of gas released as bubbles.

Freshwater ecosystems worldwide emit nearly half as much carbon dioxide and methane as fossil fuel combustion. On the Amazon-Cerrado frontier, where Tanguro is located, there are hundreds of thousands of small agricultural reservoirs, which are important, yet overlooked, greenhouse gas sources. These artificial ponds—installed to provide drinking water for cattle, facilitate road crossings, or supply energy at the farm scale—can persist for decades, creating low-oxygen conditions that drive methane production.

(left to right) Dietrich, Science Writer and Editor Sarah Ruiz, and Santarém float on a Tanguro reservoir, waiting for the methane chamber to calibrate.

photo by Mitch Korolev

Monthly sampling of six reservoirs over a year by Water Program Director Dr. Marcia Macedo revealed high methane and carbon dioxide emissions, varying with season and reservoir size. But these measurements did not capture the significant variability that can occur on daily, monthly, and annual time scales, including transient “hot spots” and “hot moments” of high greenhouse gas emissions.

This lack of frequent measurements hinders climate scientists’ ability to integrate emissions at the reservoir scale in order to estimate cumulative greenhouse gas emissions at the landscape scale. The autonomous floating chambers will address that gap, enabling comprehensive carbon monitoring and modeling of the reservoirs.

From the tropics to the Arctic

Additionally, these chambers are versatile tools that can be used across different environments. Funded by a subsequent FCS grant, six new floating chambers will accompany me to the Yukon-Kuskokwim Delta, Alaska, this summer to measure greenhouse gas emissions from Arctic ponds. The chambers will supply the frequent data necessary to constrain the LAKE model utilized by Arctic Program scientists Dr. Elchin Jafarov and Andrew Mullen. The model predicts variations in carbon emissions from ponds, providing insight into processes regulating methane and carbon dioxide. By applying the LAKE model to both Arctic ponds and Amazon reservoirs, we can gain a deeper understanding of their impacts on regional greenhouse gas budgets.

“Deploying floating chambers will streamline the process of gathering aquatic data and enhance the temporal resolution of the data, which is vital for modeling and currently absent in existing datasets,” notes Jafarov.

Dietrich and Santarém deploy another chamber on a reservoir at Tanguro Research Station.

photo by Mitch Korolev

Problem-solving and collaboration

While calibrating the low-cost sensors in our boat one March afternoon, Santarém and I noticed the linear actuator on another nearby chamber wasn’t retracting and extending as it should. Expecting another replacement was in store, we tuned into the radio and popped open the electronics case to check for “symptoms.” Blinking lights and radio silence revealed an entirely new and perplexing issue causing the malfunction.

Building this system from the ground up over the last year, the one constant has been mind-bending electronics puzzles that keep me up at night. As a biogeochemist by training, these problems usually require some tinkering, a dictionary, a lot of Googling, and sometimes bugging electrical engineers down the street at the Woods Hole Oceanographic Institution (Lane Abrams) and Spark Climate Solutions (Bashir Ziady), whose advice and contributions have substantially improved the chambers’ electrical designs. Each problem can usually be traced to a perfectly logical, satisfying solution, leaving me feeling wiser and excited to tackle the next one. I’ve tracked this new problem down to something potentially involving a “memory-leaking variable declaration” in my new bubble trap programming code. I might’ve fixed it with a “watchdog timer.” Both are new words for me, too. If the watchdog timer doesn’t pan out, Santarém and I will try another fix.

Dietrich presents her chambers to visitors at Tanguro Research Station.

photo by Mitch Korolev

Designing, building, and testing these chambers has been an iterative and constantly evolving process. What works well? What doesn’t? How can we do this more simply? Using less energy? For a lower cost? How can we improve the design so that other researchers can easily build these floating chambers as well? Soon we plan to publish open-source instructions detailing how to build and troubleshoot the floating chambers—I have already sent preliminary instructions to three interested research groups. I’m lucky to collaborate with many talented people from Woods Hole to Maine and Brazil, many of whom are as new to chambers and fluxes as I am to engineering. Nevertheless, these floating chambers incorporate a brilliant flourish from each of them.

Latest in Water

- In The News

Notes from an ecologist: Factoring in rivers and streams when studying bay health

- In The News